Flat slab, in most circumstances, the slab type suitable for many occasions is a flat (beamless, or full) slab. As the formwork and reinforcement work is simplified in beamless slabs, ease of application is provided, thus shortening the construction time. Since the structural height can be designed at a minimum level, the floor and hence building heights are also reduced. As a flat ceiling is formed, mechanical and electrical installations can be laid easily.

However, a flat slab makes the structure heavier.

The design of a heavier structure makes the structure recursively heavier with additional structural elements. As the self-weight of the building increases, the effects of earthquake forces, deflections that will occur in the slabs, etc. will also increase. In addition, depending on the ground conditions, a heavier structure may also cause an increase in soil improvement costs.

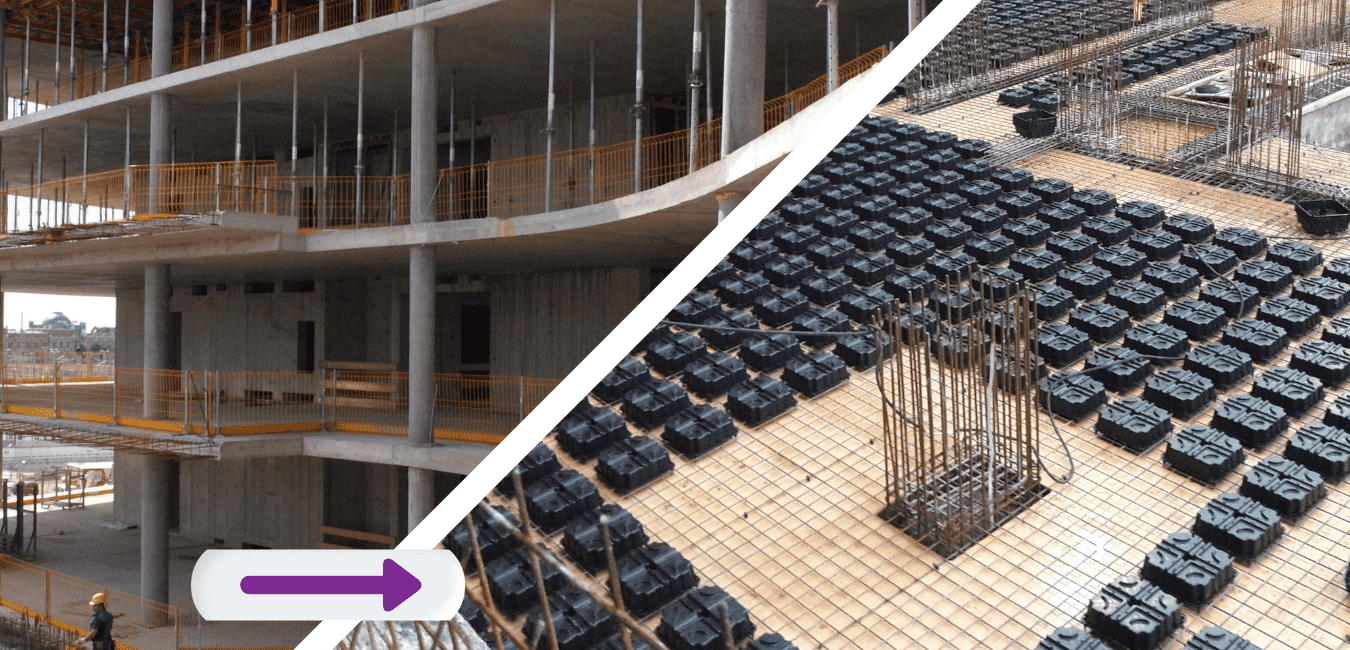

In most projects, VOLIMAX voided slab system can be easily preferred instead of flat slab to lighten the structure. Slabs designed with the voided slab system can reduce the weight of the building by up to 25% compared to flat slabs.

VOLIMAX voided slab system reduces the weight and thickness of the slab, increasing the earthquake resistance of the structure without compromising performance attributes of a flat slab.

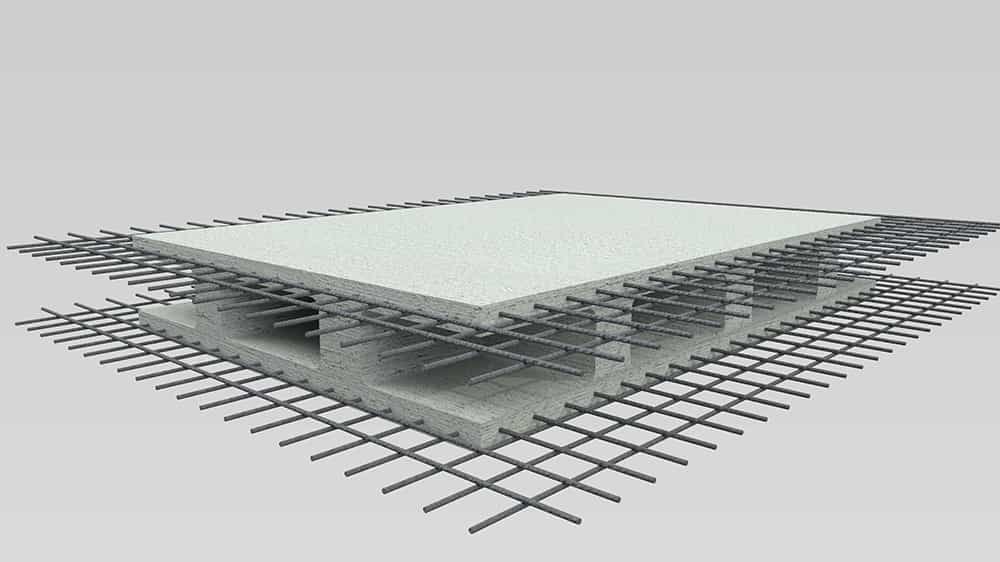

Beamless voided slab distributes the design loads to the four sides, transferring them to the columns/walls or beams.

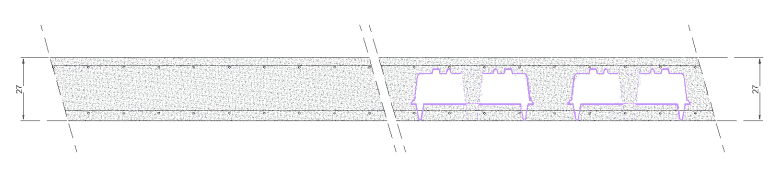

Voided slab disposable formworks create a matrix of 𝙸 shaped beams working in both directions of the plane.

VOLIMAX voided slabs are constructed bidirectionally through the use of cube shaped disposable formworks made of recycled PP that are placed between lower and upper steel reinforcement. Casting of concrete is always in-situ.

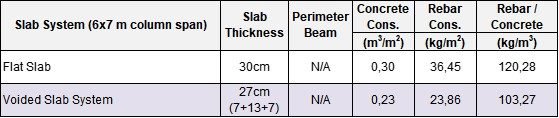

Sample comparison table:

Copyrights © 2020 All Rights Reserved by ABS Yapı Elemanları