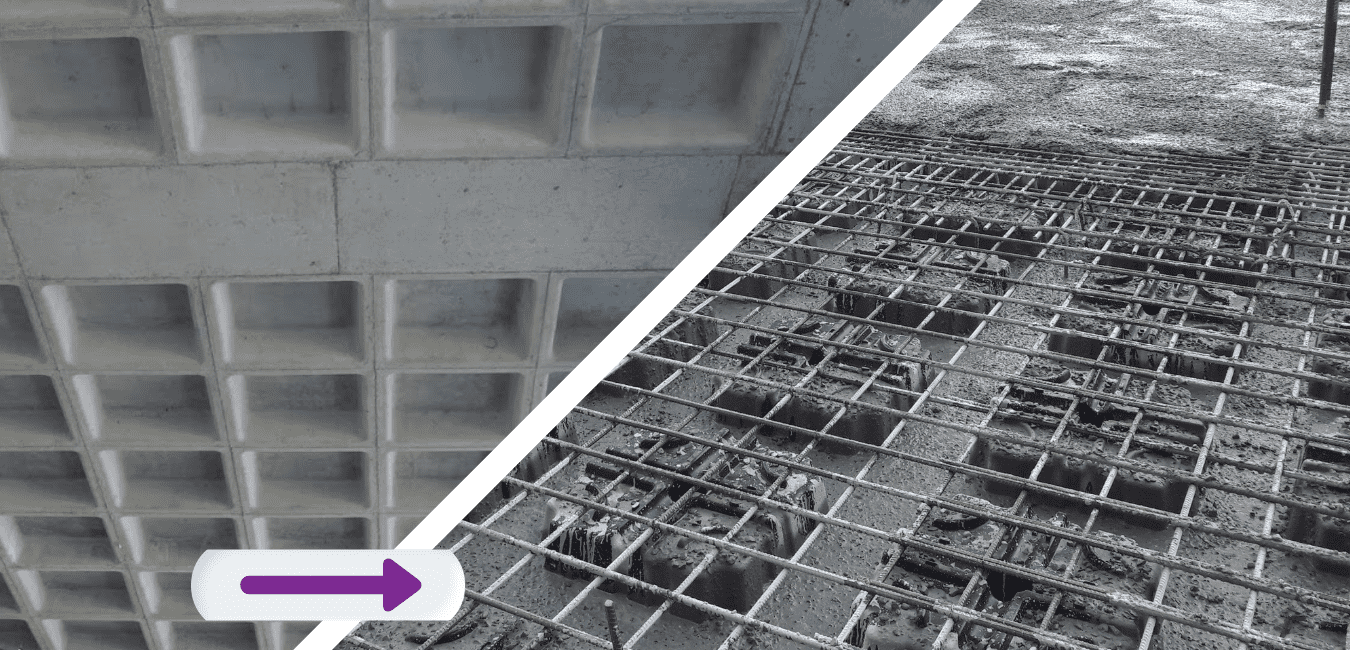

A waffle slab, also known as a bidirectional ribbed slab, is a structural system with a flat top and with beams in both directions on its bottom surface constructing a grid-like structure. The top of the ribbed slab is normally thin, and the lower grid lines are usually beams laid perpendicular to each other of equal depth. The waffle slab system has two-way reinforcement. All beams are routed from column heads or beams. The depth of the preserved ribs is the same as the column head or beam depth. The system is recommended for floors with larger spans due to bidirectional reinforcement.

In this design, cavities are created in the slab by using reusable waffle molds. In such ribbed slabs, there are generally beams with a depth of 30-35 cm in both directions and very few shear walls are constructed above the ground. Therefore, the main beams, which must meet the horizontal loads and transfer the loads to the vertical elements, are usually insufficient in structures of 5 floors and above due to their maximum depth of 35 cm, or it is necessary to increase the use of shear walls significantly.

In addition, while finding the right size and a sufficient number of waffle molds is a problem in small projects, there is a serious need for waffle molds in order to progress quickly in large constructions.

Compared to waffle slab, VOLIMAX voided slab system increases the earthquake resistance of the structure by creating a more rigid diaphragm and significantly shortens the construction time thanks to its logistical advantages and ease of application.

VOLIMAX voided slab system reduces the weight and thickness of the slab, increasing the earthquake resistance of the structure without compromising the performance attributes of a flat slab.

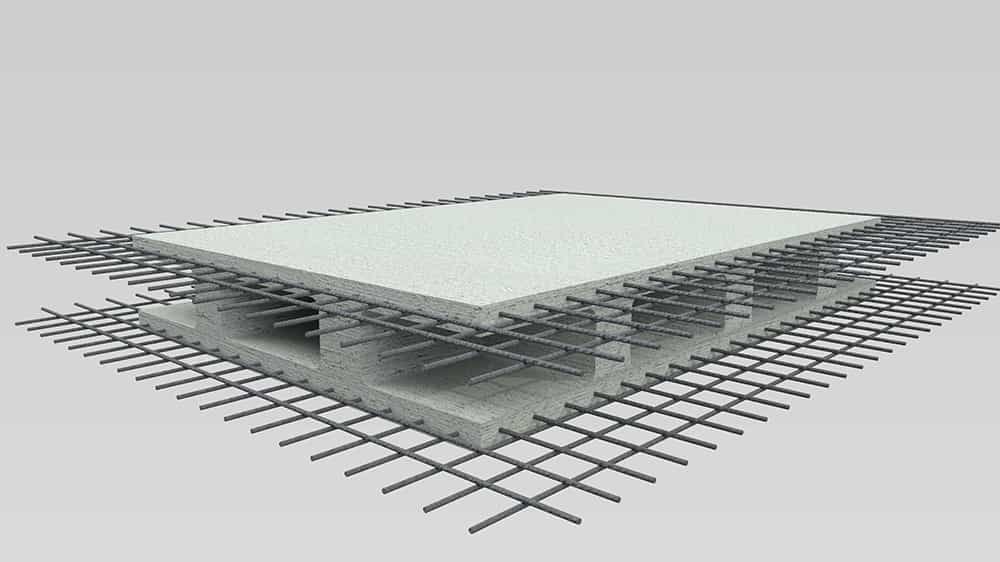

Beamless voided slab distributes the design loads to the four sides, transferring them to the columns/walls or beams.

Voided slab disposable formworks create a matrix of 𝙸 shaped beams working in both directions of the plane.

VOLIMAX voided slabs are constructed bidirectionally through the use of cube shaped disposable formworks made of recycled PP that are placed between lower and upper steel reinforcement. Casting of concrete is always in-situ.

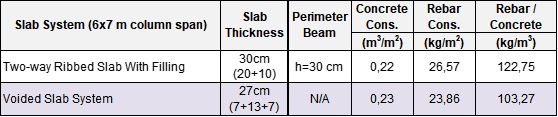

Sample comparison table:

Copyrights © 2020 All Rights Reserved by ABS Yapı Elemanları