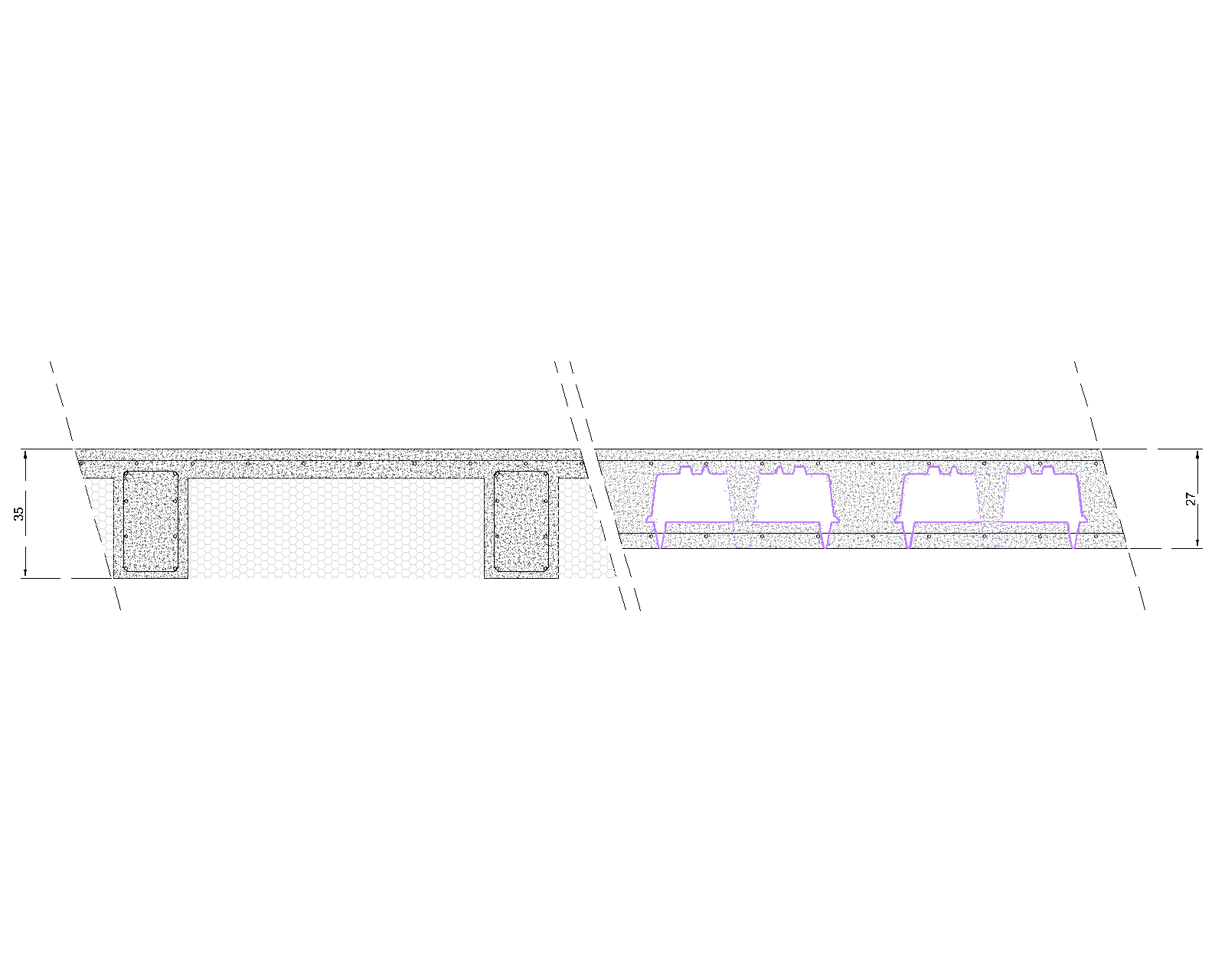

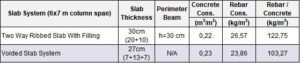

Flat slab increases self-weight

Designing a heavier structure makes the structure even heavier with additional elements recursively. As the self-weight of the structure increases, the effects of earthquake forces, deflections on the floor, etc. will also increase. Depending on the ground conditions, as the structure gets heavier the ground improvement costs may increase exponentially.