Fill in the form below or contact our experienced engineers by calling +90 216 518 02 55 to get more information, to have your project studied and to get a hollow flooring system offer.

Reach us: +90 (216) 518 02 55

Send e-mail: info@absyapi.com.tr

Slabs designed with the voided slab system can reduce the weight of the building by up to 25% compared to flat slabs. Voided Slab vs Flat Slab

Slabs designed with the voided slab system increase the earthquake resistance of the structure by creating a more rigid diaphragm compared to one way ribbed slabs. The design of traditional one way ribbed slabs have been limited by rules and regulations. One way ribbed slabs have beams with a depth of 30-35 cm in only one direction and usually very few shear walls are utilized. Therefore, the main beams, which must meet the horizontal loads and transfer the loads to the vertical elements, are usually insufficient in structures of 5 floors and above due to their maximum depth of 35 cm.

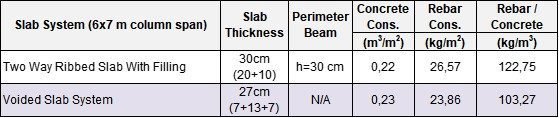

Instead, two way ribbed slabs can be constructed. However, in this design, filling the two way ribbed gaps with EPS, hollow brick or aerated concrete, especially in housing projects, should be evaluated carefully. While EPS fillings can pose a serious fire risk due to gas compression, toxic smoke emission and/or contribution to the fire by dripping, hollow brick/aerated concrete fillings also have a risk of falling during an earthquake. Voided Slab vs Ribbed Slab

Safely use the voided slab system in your projects with our 10+ years of design, field, and application experience, the only one in Turkey.

Copyrights © 2020 All Rights Reserved by ABS Yapı Elemanları