Ribbed slab, the slabs formed by dividing the slab between main beams with one way or double-sided stirrup-wrapped mini beams at maximum 70 cm intervals are called ribbed slabs. The fact that the slabs are being formed in one or two directions is called one-way ribbed slabs and two-way ribbed slabs accordingly.

The gaps between these ribs can be filled with various light filling materials such as hollow bricks or EPS (Styrofoam). Filling the gaps as such is the preferred method of application to obtain a flat ceiling. Architectural advantages can be achieved thanks to this flat ceiling.

The design of traditional one way ribbed slabs have been limited by rules and regulations. One way ribbed slabs have beamed with a depth of 30-35 cm in only one direction and usually, very few shear walls are utilized. Therefore, the main beams, which must meet the horizontal loads and transfer the loads to the vertical elements, are usually insufficient in structures of 5 floors and above due to their maximum depth of 35 cm.

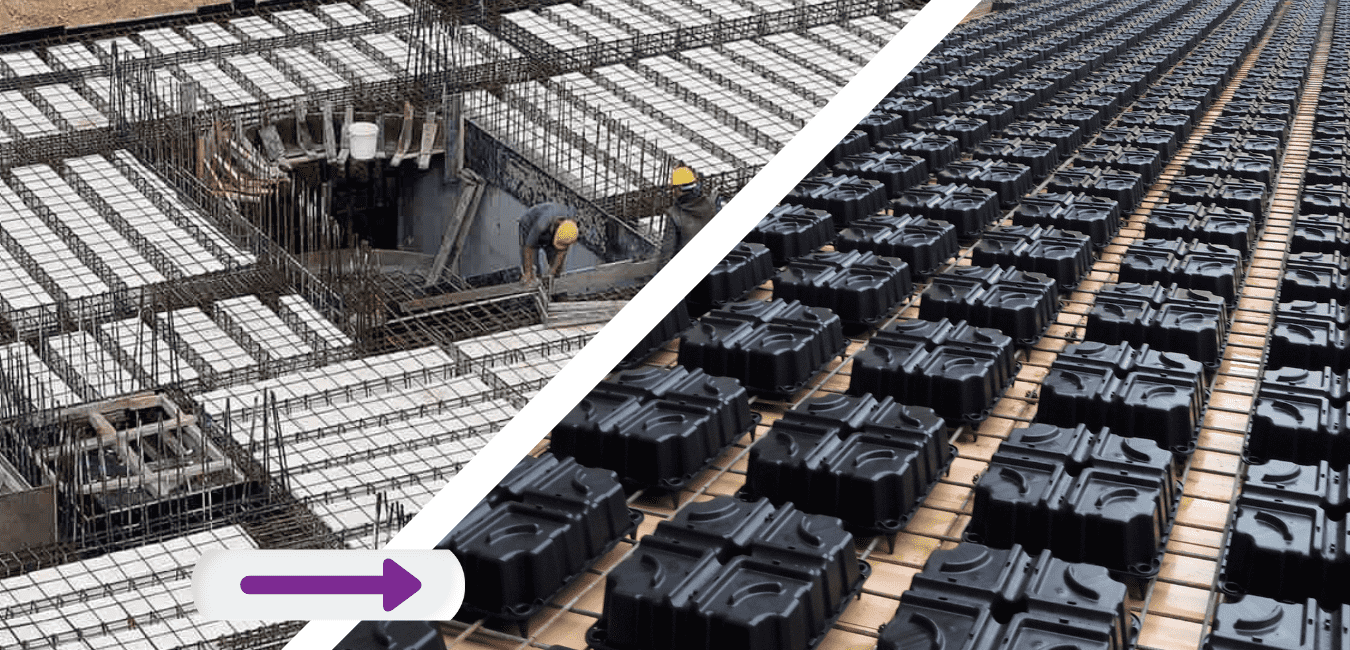

Instead, two-way ribbed slabs can be constructed. However, in this design, filling the two way ribbed gaps with EPS, hollow brick or aerated concrete, especially in housing projects, should be evaluated carefully. While EPS fillings can pose a serious fire risk due to gas compression, toxic smoke emission and/or contribution to the fire by dripping, hollow brick/aerated concrete fillings also have a risk of falling during an earthquake.

Compared to ribbed slab, VOLIMAX voided slab system increases the earthquake resistance of the structure by creating a more rigid diaphragm. Additionally, it eliminates the risk of fire with EPS fillings since it constructs a concrete flat ceiling.

VOLIMAX voided slab system reduces the weight and thickness of the slab, increasing the earthquake resistance of the structure without compromising performance attributes of a flat slab. Read advantages of the voided slab system.

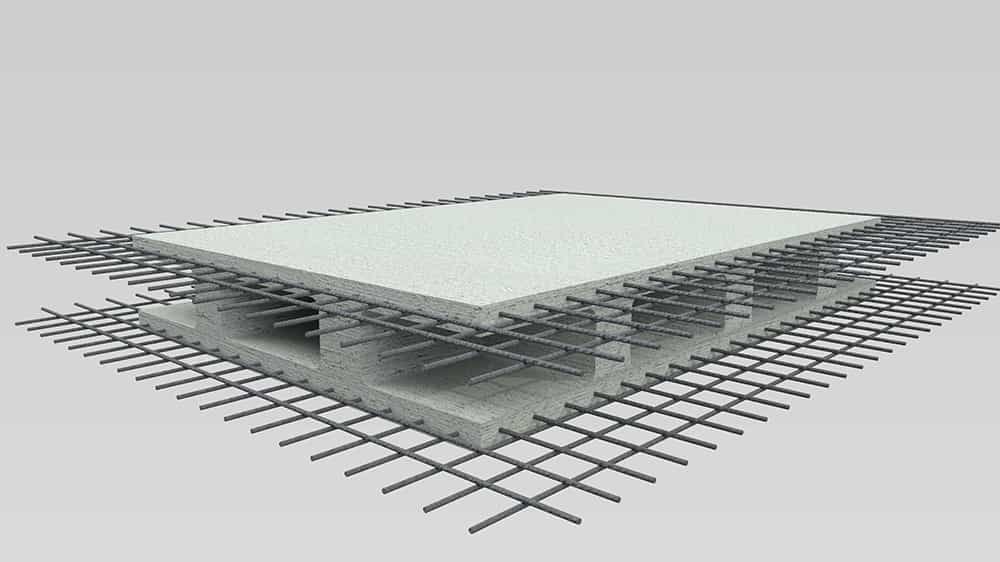

Beamless voided slab distributes the design loads to the four sides, transferring them to the columns/walls or beams.

Voided slab disposable formworks create a matrix of 𝙸 shaped beams working in both directions of the plane.

VOLIMAX voided slabs are constructed bidirectionally through the use of cube shaped disposable formworks made of recycled PP that are placed between lower and upper steel reinforcement. Casting of concrete is always in-situ.

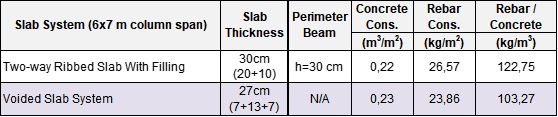

Sample comparison table:

Copyrights © 2020 All Rights Reserved by ABS Yapı Elemanları